Our Infrastructure

Pattern Storage

Our pattern storage facility ensures the safe and organized maintenance of casting patterns. Each pattern is meticulously cataloged and stored to prevent damage and maintain dimensional accuracy. This systematic approach enhances efficiency and ensures consistent quality across production runs, forming the foundation of our precision production process.

Methoding

Methoding is the critical planning stage that ensures smooth and efficient casting production. Engineers design gating and riser systems to control the molten metal’s movement, reducing waste and defects. Our expert team utilizes advanced simulation software to optimize casting parameters. Proper methoding ensures uniform solidification, minimal defects, and superior strength in the final product.

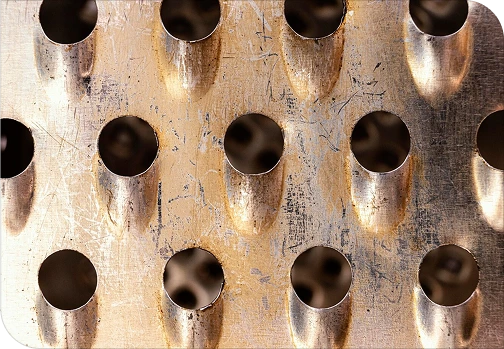

Moulding

Moulding is the process of creating precise sand molds that shape the final castings. High-quality molding sand is compacted around patterns to form cavities that will receive molten metal. Our advanced molding techniques ensure accuracy and consistency. Well-prepared molds ensure casting strength, surface finish, and dimensional precision.

Melting

Melting involves heating raw materials in induction or cupola furnaces to achieve the required molten metal composition. The temperature is carefully controlled to ensure proper fluidity and metallurgical properties. Once ready, the molten metal is poured into prepared molds with precision. This step is crucial for ensuring strength, durability, and quality in the final casting.

Fettling

Fettling is the cleaning and finishing process that removes excess material from castings. This includes removing gates, runners, and risers, and surface finishing to achieve the required shape and texture. It ensures the removal of rough edges, sand residues, and any imperfections, contributing significantly to the overall quality and precision of the final cast product.